Ben Day - Interface of Things

Where things and people connect, creating and finding ways to move your ideas forward. Free consultations.

email: ben@benday.net

Selected Work 2024-2026

Space Planning

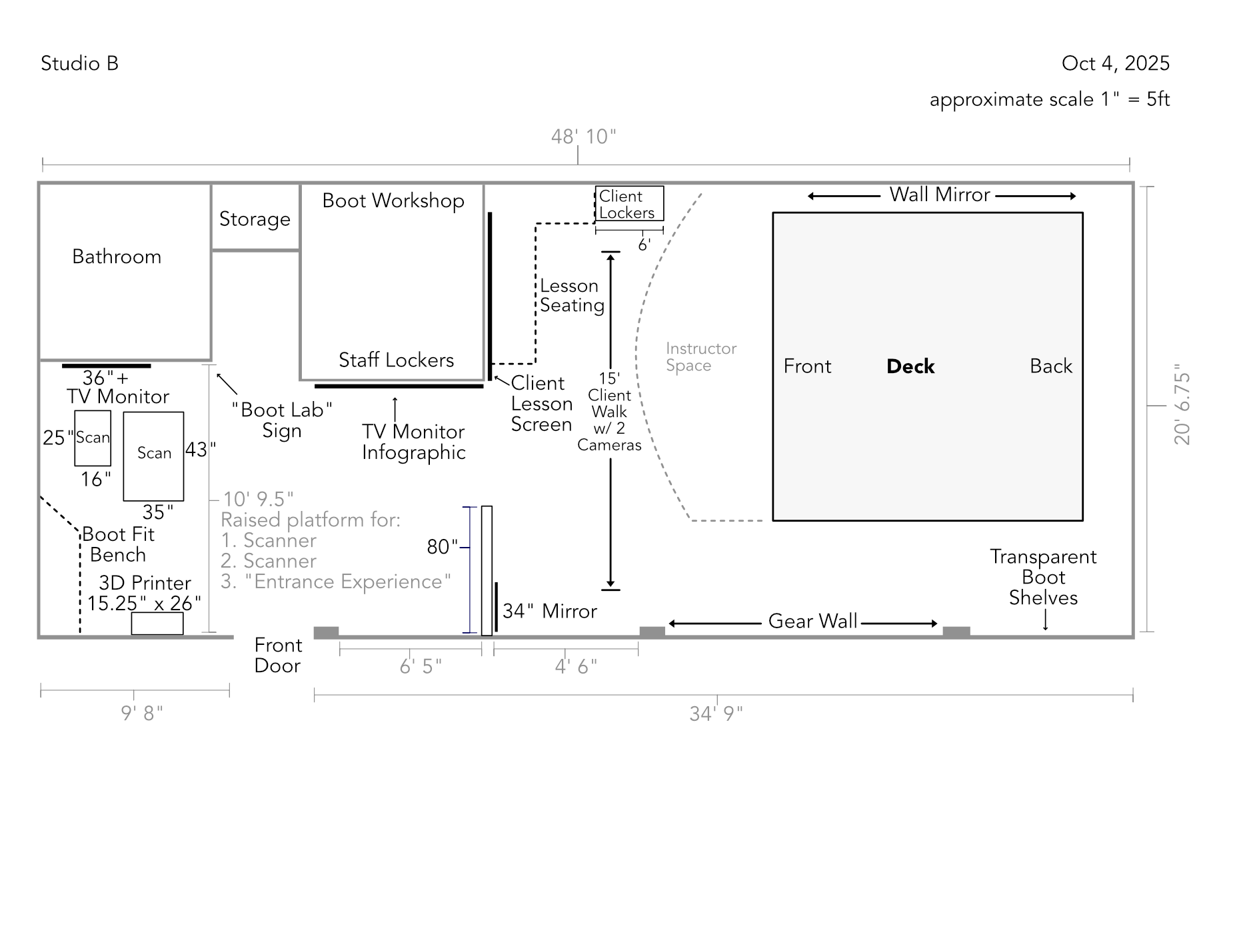

Background: Planning the layout of your project is important. Visualization and simulation can allow you to realize problems or opportunities in your ideas.

Solution: Creating maps, 3D models and measuring out spaces allows for fast ideation.

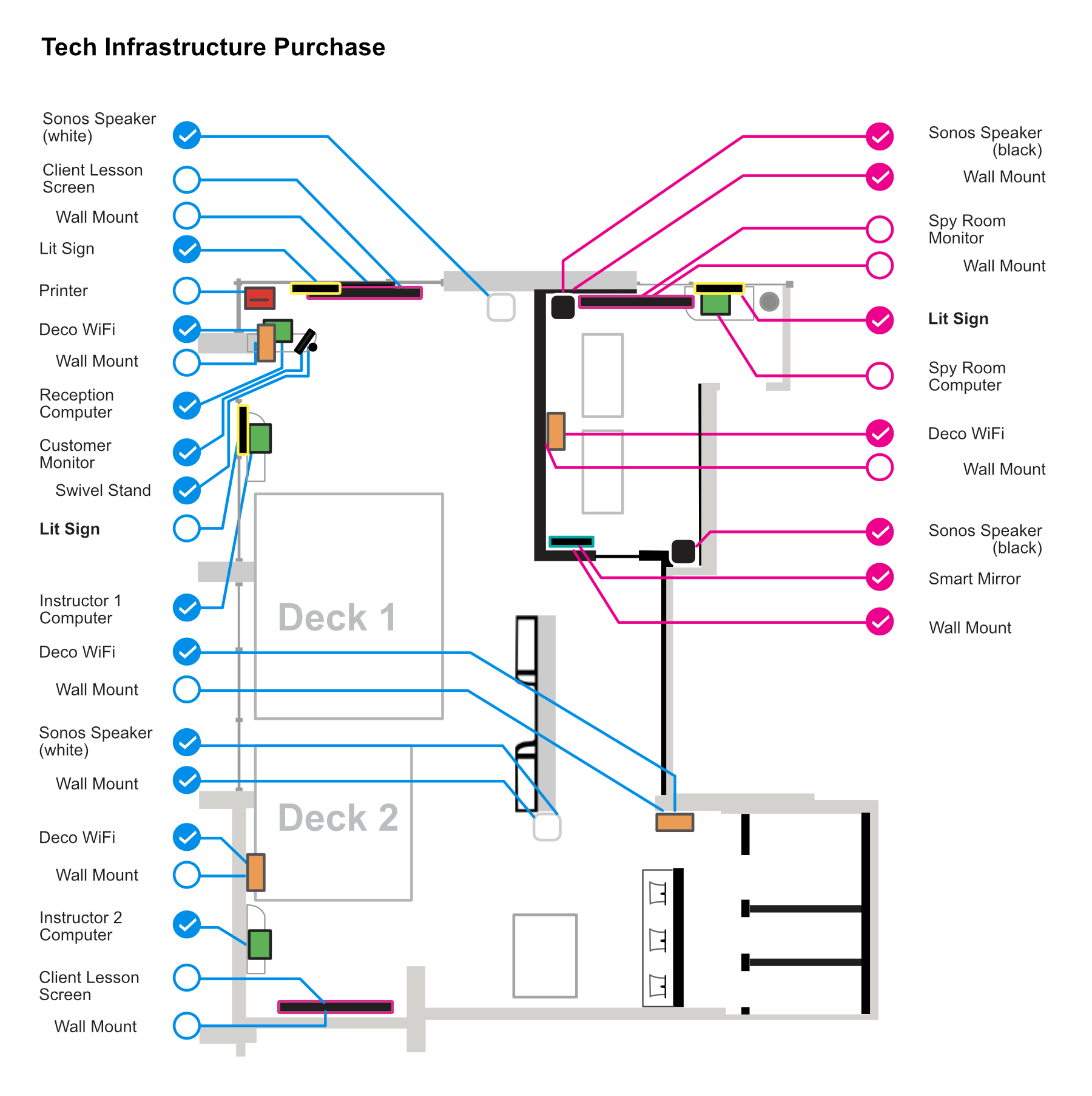

- Renderings: Once a 3D model is created, get image or video renderings to keep your ideas in track.

- Maps: Marking the location of items to install greatly aids in planning and communicating ideas to employees, contractors and investors.

- Physical Models: Limited quick basic scale mock ups can help to understand some planning decisions much better than a rendering.

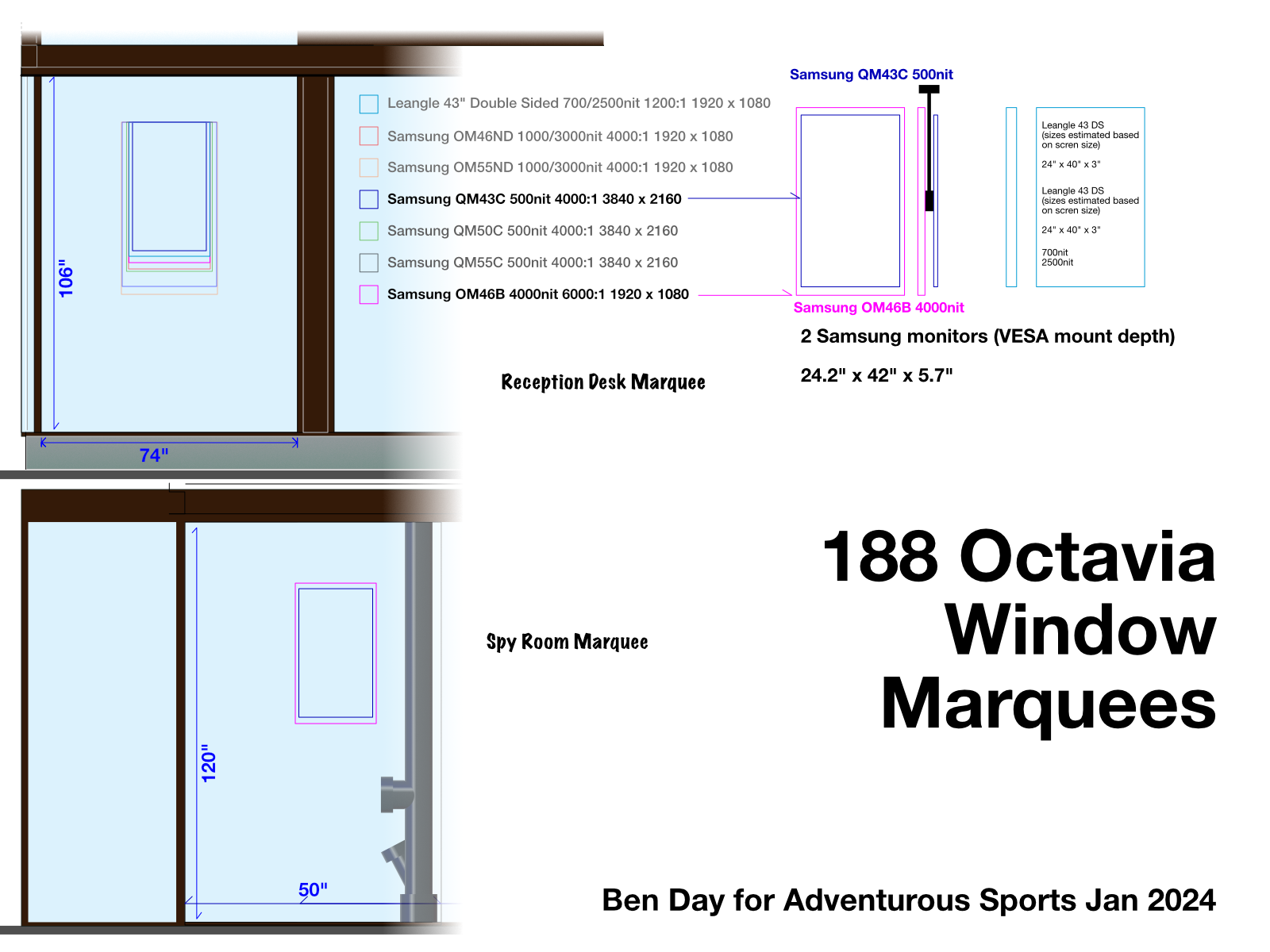

Window Marquees

Background: Using your storefront windows to advertise changing content about your services is effective and attractive.

Solution: Design and install the correct bright screens for your business. Advertising services can be expensive, but modern technology helps to roll our own systems.

- Images: Affordable hosting, design and implementation.

- Video: Ben Day can edit video a great motion graphics to convey the expereince you offer.

- Remote Operation: Ben Day can update content remotely, and set up IoT controls to power screens on and off on a timer, or manually.

Adventurous Sports - Endless Slopes

Background: Adventurous Sports, in San Francisco, CA, operates two "Endless Slope" decks for ski and snowboard training in the comfort of an indoor studio.

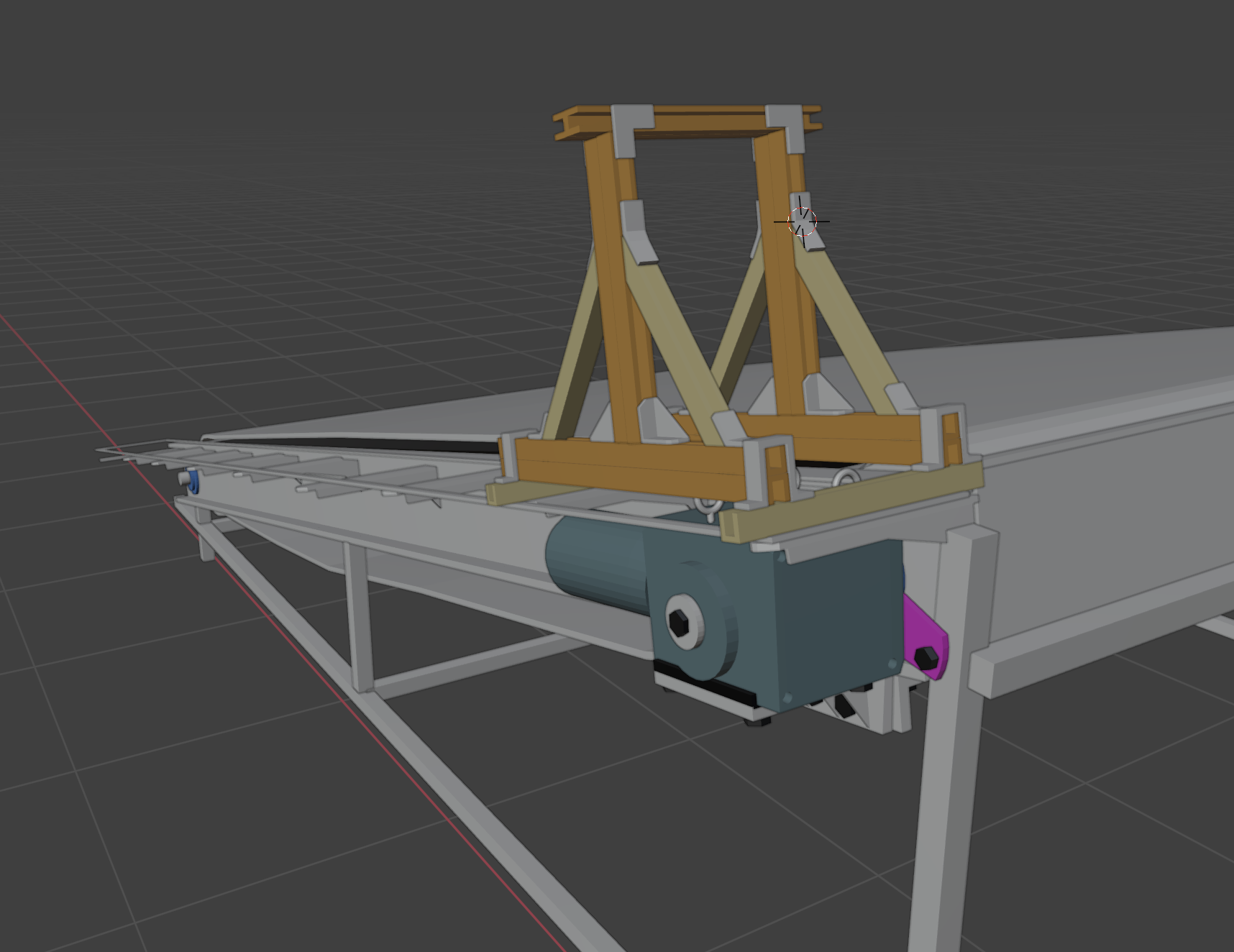

Solutions: The manufacturer of the Endless Slopes went out of business soon after the decks were installed. Problems began to arise regarding squeaking sounds, one stopped working all together, and worse yet, a robbery had stolen all of the specialized tools needed...

- Contractors: Ben Day found the certifed machine control engineering resource to replace the faulty machine control component

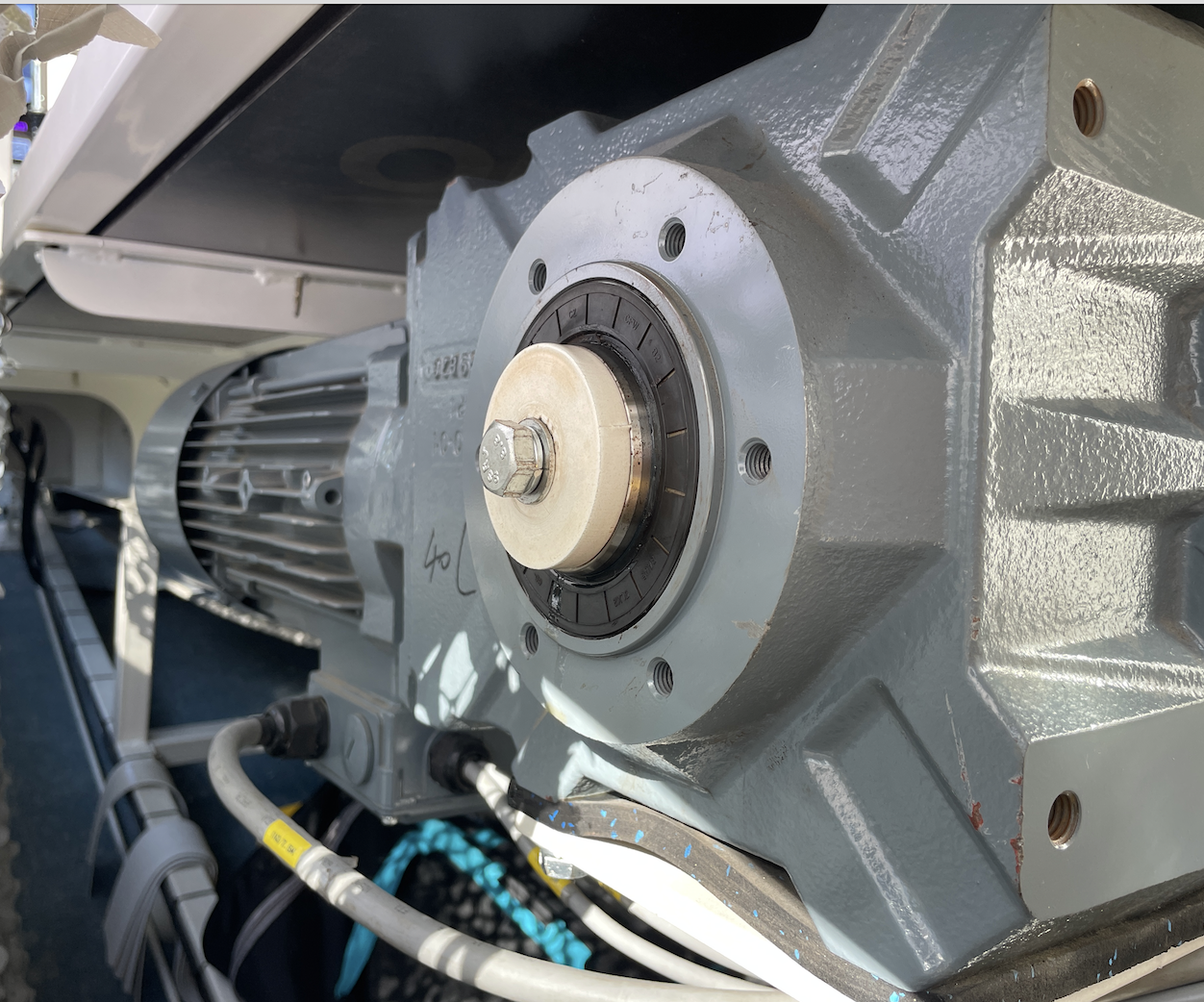

- Research: Ben Day found and consulted with local machine mechanics to identify the lack of a torque arm in the deck designs, which contributed to motor movement and squeaking coming from a flange bearing.

- Fixing: Ben Day installed temporary torque arms to reduce motor movement and extend the lifespan of the current bearings to make it through the busiest part of the winter sports season.

- Planning: Ben Day plans for the safe removal of the Bauer gearbox/motor/break control to allow for the changing of the bearing andmodification of the deck to accept a Bauer torque arm.